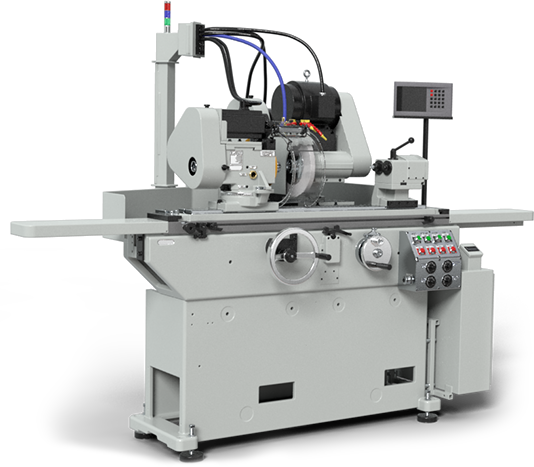

14×30 MANUAL

ID/OD CYLINDRICAL GRINDER

Our 14×30 manual cylindrical grinder is an established, proven grinding system. For parts up to 30”, this durable machine provides the stability and repeatability needed to produce your high precision components.

REQUEST QUOTE

Review and Select Your Options

Machines must pass rigorous test grinding and verification to .00005” (.00127mm) or less

| GENERAL SPECIFICATIONS | |

| OVERALL DIMENSIONS (WXDXH) | 104 IN X 41 IN X 46 IN |

| MACHINE WEIGHT (NET) | 5200 LBS (2358 KG) |

| MAX PART DIAMETER | 14 IN (355.6 MM) |

| DISTANCE BETWEEN CENTERS | 28 IN (711.2 MM) |

| WORKTABLE SIZE | 5 IN X 50 IN (127 MM X 1270 MM) |

| TABLE SWIVEL | 7 DEGREES |

| WORKHEAD SPINDLE | |

| SPEED | 0-1000 RPM |

| SPINDLE NOSE | PARKER TAPER – ACCEPTS 5C COLLETS |

| DRIVE MOTOR | 1 HP@1,750/200 RPM |

| MANUALLY PIVOTING WORKHEAD (B-AXIS) – ACCURACY 0.0005 DEGREES | |

| POWER | |

| POWER REQUIREMENT | 230, OR 480 VAC – 50/60 HZ |

| POWER CONSUMPTION | 6 KVA |

| MAX. CURRENT | 30 A |

| TOTAL POWER RATING | 10 HP (7.5 KW) |

| TABLE AXIS | |

| MANUAL AND VARIABLE SPEED ELECTRIC TABLE DRIVE | |

| HAND SCRAPED TURCITE COATED VEE & FLAT WAY SYSTEM | |

| TOTAL TRAVEL | 30 IN (762 MM) |

| TABLE FEED MOTOR | 3/4 HP @ 1,750/400 RPM |

| TABLE SWIVEL | 7 DEGREES |

| CROSSFEED AXIS | |

| MANUAL DRIVEN BALLSCREW | |

| PRECISION ROLLING ELEMENT LINEAR MOTION BEARING | |

| CLOSED LOOP POSITIONING WITH HEIDENHAIN GLASS SCALE FEEDBACK | |

| TOTAL TRAVEL | 7 IN (177.8 MM) |

THE BENEFITS BUILT INTO EVERY ONE OF OUR

CNC GRINDING MACHINES.

Hand Scraped Ways

The human touch in a high precision machine. Hand scraping provides a more accurate surface for more accurate part production.

Cast Iron Bases

Preprogrammed Cycles